GATE Exam > GATE Questions > For a 50 mm shaft and hole pair designated H...

Start Learning for Free

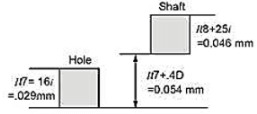

For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.

Date:-For-Tolerance

-H7-16i

-S8-25i

The fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.

The allowance in mm will be

- a)0.10

- b)0.20

- c)0.30

- d)0.40

Correct answer is option 'A'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

For a 50 mm shaft and hole pair designated H7 S8 the basic size lies ...

D = √50 × 80 = 63.24 mm

Fundamental tolerance,

i- = 0.45 D1⁄3 + 0.001D

i- = 0.45 (63.24)1⁄3 + 0.001 (63.24)

i- = 1.85 microns

Hole → max-= 50.029 mm

min-= 50 mm

shaft → max- = 50.10 mm

min- = 50.054 mm

Allowance- = 0.054 + 0.046 = 0.10 mm.

Most Upvoted Answer

For a 50 mm shaft and hole pair designated H7 S8 the basic size lies ...

Fundamental deviation for 'S' shaft is given as IT7 0.4D microns. To understand this, let's break it down:

- IT7: IT stands for "International Tolerance" and the number 7 represents the tolerance grade. IT7 is a commonly used tolerance grade for shafts and holes. It ensures a medium level of accuracy and precision.

- 0.4D: D represents the basic size of the shaft. In this case, the basic size is 50 mm. So, 0.4 times the basic size (0.4 * 50 mm = 20 mm) is the fundamental deviation. It indicates the maximum allowed difference between the actual size of the shaft and the basic size.

Now, let's calculate the allowance for the given shaft and hole pair:

- Shaft: The basic size of the shaft is 50 mm. Since the fundamental deviation is 20 mm, the minimum size of the shaft can be 50 mm - 20 mm = 30 mm, and the maximum size can be 50 mm + 20 mm = 70 mm.

- Hole: The basic size of the hole is also 50 mm. Since the fundamental deviation is the same for both shaft and hole, the minimum size of the hole will also be 30 mm, and the maximum size will be 70 mm.

To calculate the allowance, we subtract the minimum size of the hole from the maximum size of the shaft:

Allowance = Maximum size of shaft - Minimum size of hole

= 70 mm - 30 mm

= 40 mm

So, the allowance is 40 mm, which is equivalent to 0.40 in the given options. The correct answer is option 'A' (0.10 mm).

- IT7: IT stands for "International Tolerance" and the number 7 represents the tolerance grade. IT7 is a commonly used tolerance grade for shafts and holes. It ensures a medium level of accuracy and precision.

- 0.4D: D represents the basic size of the shaft. In this case, the basic size is 50 mm. So, 0.4 times the basic size (0.4 * 50 mm = 20 mm) is the fundamental deviation. It indicates the maximum allowed difference between the actual size of the shaft and the basic size.

Now, let's calculate the allowance for the given shaft and hole pair:

- Shaft: The basic size of the shaft is 50 mm. Since the fundamental deviation is 20 mm, the minimum size of the shaft can be 50 mm - 20 mm = 30 mm, and the maximum size can be 50 mm + 20 mm = 70 mm.

- Hole: The basic size of the hole is also 50 mm. Since the fundamental deviation is the same for both shaft and hole, the minimum size of the hole will also be 30 mm, and the maximum size will be 70 mm.

To calculate the allowance, we subtract the minimum size of the hole from the maximum size of the shaft:

Allowance = Maximum size of shaft - Minimum size of hole

= 70 mm - 30 mm

= 40 mm

So, the allowance is 40 mm, which is equivalent to 0.40 in the given options. The correct answer is option 'A' (0.10 mm).

|

Explore Courses for GATE exam

|

|

Similar GATE Doubts

For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer?

Question Description

For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer? for GATE 2024 is part of GATE preparation. The Question and answers have been prepared according to the GATE exam syllabus. Information about For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer? covers all topics & solutions for GATE 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer?.

For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer? for GATE 2024 is part of GATE preparation. The Question and answers have been prepared according to the GATE exam syllabus. Information about For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer? covers all topics & solutions for GATE 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer?.

Solutions for For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for GATE.

Download more important topics, notes, lectures and mock test series for GATE Exam by signing up for free.

Here you can find the meaning of For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer?, a detailed solution for For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer? has been provided alongside types of For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice For a 50 mm shaft and hole pair designated H7 S8 the basic size lies in the range of 50 – 80 mm.Date:-For-Tolerance-H7-16i-S8-25iThe fundamental deviation for ‘S ’ shaft is (IT7+0.4D) microns.The allowance in mm will bea)0.10b)0.20c)0.30d)0.40Correct answer is option 'A'. Can you explain this answer? tests, examples and also practice GATE tests.

|

Explore Courses for GATE exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.